Data Historian

In a world where Industry 4.0 is redefining standards of productivity and efficiency, the archiving of industrial data plays a crucial role. Companies are increasingly looking to leverage their data to improve performance, reduce costs, and ensure regulatory compliance. This is where AVEVA comes into play with a suite of industrial data archiving and analysis solutions.

Retrieve, collect and store data

Presentation

Real-time monitoring, predictive maintenance, and informed decisions with Data Historian

The archiving of industrial data involves collecting, archiving, and analyzing information generated by industrial processes. This includes data from sensors, production equipment, energy management systems, and much more. A data historian allows real-time monitoring of operations, thus optimizing process performance and efficiency. It also facilitates predictive maintenance, reducing downtime and extending equipment lifespan. By ensuring complete traceability and providing accurate records, it helps companies comply with regulations and prepare for audits. Moreover, data analytics and the analysis of historical trends enable informed strategic decision-making, continuously improving operations and reducing costs. In summary, the collected data play a crucial role in enhancing performance, managing resources, and ensuring regulatory compliance.

Why Implement a Data Historian?

Performance Optimization

By analyzing historical data, companies can identify trends and anomalies, enabling them to optimize processes and prevent failures before they occur.

Regulatory Compliance

Industries are often subject to strict safety and environmental regulations. Data archiving helps prove compliance and meet audit requirements.

Innovation and Development

Archived data can serve as a foundation for developing new products and services, providing valuable insights into past performance.

prev

next

Main AVEVA Predictive maintenance features

Centralize the archiving of process and alarm data

AVEVA Historian offers a high-performance archiving system that is ready to use immediately upon installation. Its user-friendly administration does not require any database expertise, making it accessible for all users. Additionally, data acquisition via Store & Forward ensures that no data is lost, providing a reliable and efficient solution for centralizing process and alarm data archiving.

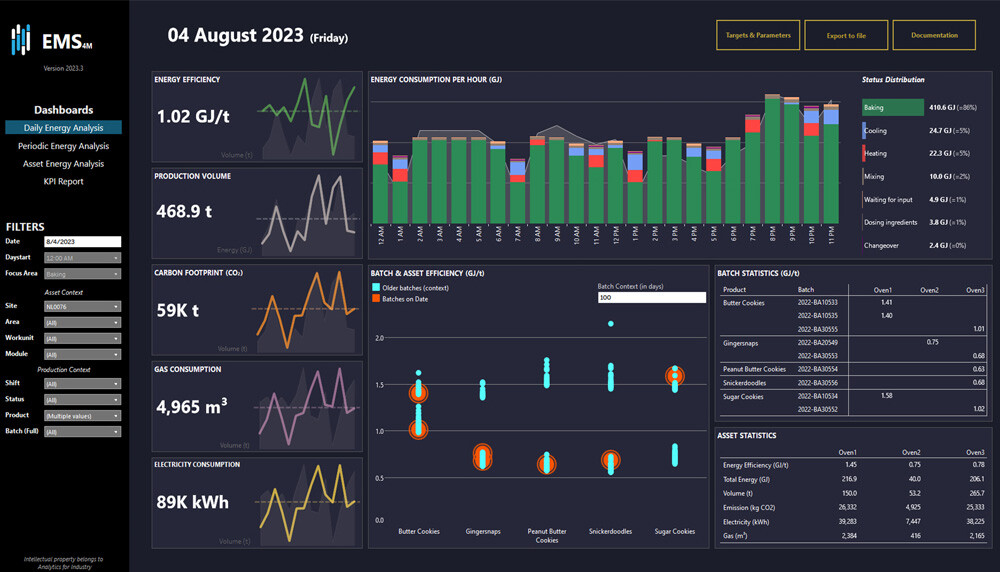

Leverage Archived Data

AVEVA Historian offers a user-friendly interface accessible from a web browser, allowing users to easily create dashboards. The recorded content can also be integrated into other solutions, providing great flexibility and facilitating data analysis and visualization. This accessibility and integration make monitoring and optimizing industrial performance more efficient and transparent. Additionally, the ability to customize dashboards enables users to visualize the most relevant data for their specific needs.

Analysis of Archived Data in Historian

AVEVA Historian simplifies the extraction and analysis of archived data for optimal utilization. Through the Web API, users can retrieve raw data or present it in diagram form. The Historian add-on for Excel allows easy extraction of real-time, historical, or aggregated data directly into Excel, adding a dedicated menu for this task. Additionally, the Historian Data REST API offers an alternative method for data extraction. Users can create trend profiles and preformat archived data with Query for reports, enabling advanced and flexible data analysis.

Which AVEVA software meets your Data Historian needs?

AVEVA Historian

With AVEVA Historian, collect and archive all your data to build up an industrial Big Data and unlock the hidden potential for improvement in your operations.

Data Management

AVEVA PI Data Infrastructure

Hybrid solution ready to manage your operational data, from the Edge to the Cloud.

Data Management

AVEVA Insight

Self-service dashboards and customizable alerts to optimize your production and generate OEE (Overall Equipment Effectiveness) metrics using process analytics.

Data Management

prev

next

Take your data analytics and AI strategy further.

Reduction of energy consumption

Predictive maintenance

Reduce greenhouse gas emissions and operational costs. Comply with stringent environmental regulations and meet sustainability goals. Discover strategies for carbon footprint reduction, eco-friendly practices, green technology, and improving corporate social responsibility (CSR). Prioritize sustainability and energy efficiency.

By implementing a predictive maintenance strategy, you gain actionable data for your maintenance and asset management approach. Industrial operators must adopt predictive maintenance to anticipate anomalies and reduce costs.

Learn more

Data analytics & AI: Latest News

prev

next

prev

next

![[Interview] How does AVEVA support the cosmetics and pharmaceutical industries in their digitalization?](https://www.factorysoftware.com/hs-fs/hubfs/FSO/Blog_2024/ENG/digital-transformation-life-sciences.jpg?width=680&height=460&name=digital-transformation-life-sciences.jpg)